Yes, you can glue concrete to concrete. While this might surprise some, it’s a reliable and often essential technique in construction and repair work. Using the right adhesive and proper preparation, you can achieve a durable and lasting bond.

Concrete, known for its durability and strength, often requires repair or extension. Cement-based adhesives like polyurethane mortar or epoxy provide robust and flexible bonding solutions for these tasks. Polyurethane mortar is ideal for environments with varying temperatures and humidity, while epoxy adhesives offer quick drying times and high strength, perfect for heavy-duty applications.

Key Takeaways:

- Concrete Adhesion: Yes, concrete can be glued to concrete effectively.

- Adhesive Types: Polyurethane mortar and epoxy are popular choices.

- Preparation: Properly cleaning and preparing the surface is crucial.

- Application Tools: Use putty knives or caulking guns for applying adhesive over cracks or holes.

- Adhesive Options: Gorilla Glue works on raw bricks or cement but may struggle with cured concrete.

Understanding the right techniques and materials can save time and enhance the integrity of your concrete projects. Dive into the details to make your next concrete bonding task a success.

Table of Contents

Types of Glues for Concrete

Concrete adhesives come in various types, each suited for specific applications and bonding requirements. Understanding these options helps ensure strong, durable bonds in your concrete projects.

Polyurethane Mortar

- Applications: Ideal for general bonding of concrete, bricks, and tiles. Often used in outdoor settings due to its flexibility and resistance to temperature and humidity variations.

- Benefits: Provides strong bonds, flexible, suitable for varying environmental conditions.

- Example Use: Securing paving stones in a garden walkway.

Epoxy Adhesives

- Applications: Best for heavy-duty applications where high strength and quick drying are required. Commonly used in industrial settings and for structural repairs.

- Benefits: High strength, quick drying time, excellent for heavy loads and structural integrity.

- Example Use: Repairing structural cracks in a concrete wall.

Acrylic Adhesives

- Applications: Useful for bonding concrete to other materials such as metal or wood. Often employed in decorative applications.

- Benefits: Strong bond, versatile, good for mixed material projects.

- Example Use: Attaching metal railings to concrete steps.

Latex-Based Adhesives

- Applications: Primarily used for indoor applications, such as tiling or minor concrete repairs. Suitable for lighter, non-structural projects.

- Benefits: Easy to use, good adhesion, and cleanup is simple with water.

- Example Use: Securing ceramic tiles to a concrete bathroom floor.

Polyvinyl Acetate (PVA) Adhesives

- Applications: Best for minor repairs and as a primer for painting concrete surfaces. Works well in low-stress environments.

- Benefits: Easy to apply, good initial grab, affordable.

- Example Use: Sealing concrete walls before applying paint.

Best Glue for Concrete

The best glues for bonding concrete to concrete vary based on the scale and type of the project. Here are the top recommended options:

| Product | Best For | Description |

| PC Products 72561 PC-Concrete Two-Part Epoxy Adhesive | Strong and durable bonding | This two-part epoxy adhesive is renowned for its exceptional strength, making it ideal for heavy-duty applications and structural repairs. |

| Loctite PL 500 Landscape Block Adhesive | Outdoor projects | Specially formulated for bonding landscape blocks, bricks, and pavers, this adhesive offers long-lasting durability and weather resistance. |

| Quikrete Construction Adhesive | General concrete bonding | This versatile construction adhesive is perfect for a variety of concrete applications, providing a robust and lasting bond. |

| Gorilla Glue | Small repairs | Gorilla Glue is excellent for smaller concrete repairs. It expands slightly as it cures, filling gaps and providing a strong hold. |

| Loctite PL Premium Polyurethane Construction Adhesive | Heavy-duty projects | This premium adhesive provides superior strength and can bond almost any material, making it a top choice for large-scale concrete bonding. |

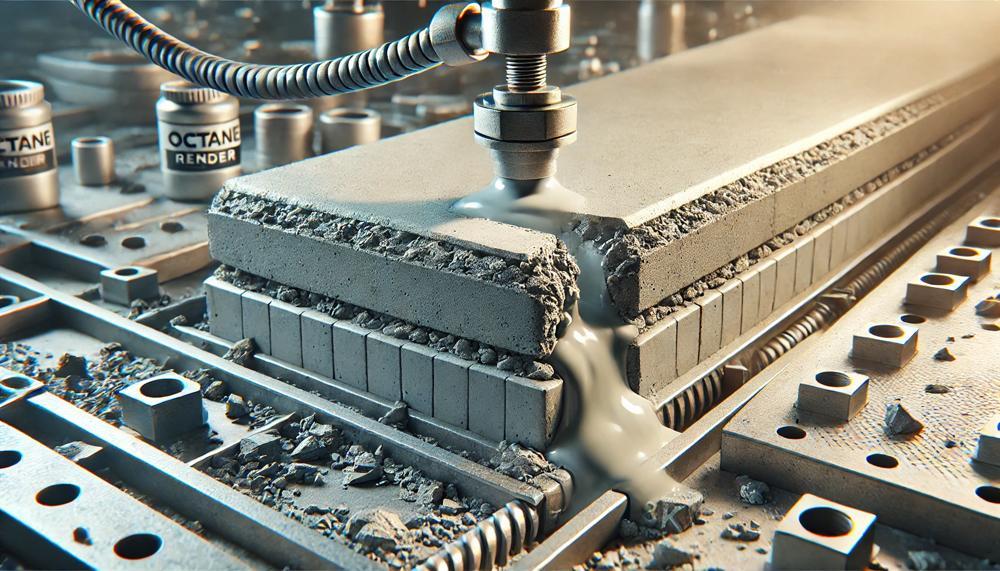

How to Glue Concrete to Concrete

Gluing concrete to concrete requires meticulous preparation and the right materials. Follow these steps for a successful bond:

Understand Concrete Properties

- Know the strengths and weaknesses of concrete.

- Recognize that concrete is porous and rough, making preparation crucial.

Clean and Prepare Surfaces

- Remove loose or crumbling concrete.

- Use a wire brush or pressure washer to clean thoroughly.

- Ensure the surface is dry and free of dust and debris.

- Roughen the surface if it’s too smooth using a chisel or grinder.

Choose the Right Adhesive

- Select an adhesive specifically designed for concrete, such as epoxy or polyurethane-based adhesives.

- Epoxy adhesives are known for their quick drying time and high strength, ideal for heavy-duty applications.

- Polyurethane mortars provide strong bonds and flexibility, suitable for various temperatures and humidity levels.

Apply the Adhesive

- Follow the manufacturer’s instructions for mixing and applying the adhesive.

- Apply the adhesive evenly to both surfaces using a putty knife or caulking gun.

- Cover any cracks or holes to ensure a complete bond.

Exert Pressure

- Press the surfaces together firmly to eliminate air gaps.

- Use clamps or weights to maintain pressure while the adhesive cures.

- Refer to the adhesive’s curing time in the instructions, which can vary.

Seek Expert Guidance

- For complex projects or specific recommendations, consult with a professional.

- Ensure you are using the best product for your particular application.

Surface Preparation and Curing

- Proper surface preparation is key: clean, dry, and roughen the surface as needed.

- Allow the adhesive to cure fully for a strong and durable bond.

Is Elmer’s Glue a Felt-Friendly Choice?

No, Elmer’s Glue is not a suitable adhesive for bonding concrete to concrete.

| Adhesive | Suitability for Concrete | Notes |

| Elmer’s Glue | Not Suitable | Designed for paper, wood, and fabric; lacks the strength for concrete. |

| Concrete Bonding Adhesive | Highly Suitable | Specifically formulated for concrete, ensures a strong, durable bond. |

| Epoxy | Suitable | Provides a robust bond, ideal for high-stress areas. |

| Polyurethane Adhesive | Suitable | Offers excellent bonding strength and flexibility for concrete surfaces. |

Elmer’s Glue, typically a PVA (polyvinyl acetate) glue, is formulated for light craft projects involving materials like paper, wood, and fabric. It lacks the necessary adhesive strength and durability required to bond concrete, a much denser and more porous material.

For bonding concrete to concrete, you should use adhesives specifically designed for this purpose, such as concrete bonding adhesives, epoxies, or polyurethane adhesives. These products ensure a robust, lasting bond that can withstand the stress and weight that concrete surfaces typically endure.

Elmer’s Glue and Fabrics: A Sticky Tale

Elmer’s Glue andamp; Fabrics: A Sticky Tale

Elmer’s Glue can indeed be used on fabrics, but its success hinges on the type of fabric and the method of application. Let’s dive into how it works and the best techniques for its application.

How Elmer’s Glue Works on Fabrics

Elmer’s Glue is a versatile adhesive, primarily known for its effectiveness on materials like paper, wood, and ceramics. When it comes to fabrics, its performance varies based on the fabric’s absorbency and texture.

Types of Fabrics and Effectiveness

- Absorbent Fabrics: Elmer’s Glue works best on absorbent fabrics such as cotton, felt, and flannel. These materials soak up the glue, allowing it to create a stronger bond.

- Non-absorbent Fabrics: Fabrics like silk, polyester, and other synthetics do not absorb the glue well, leading to weaker bonds and potential residue.

| Fabric Type | Effectiveness | Notes |

| Cotton | High | Best for crafts; strong absorption |

| Felt | Moderate | Depends on the project; good absorption |

| Flannel | High | Similar to cotton; strong bond |

| Silk | Low | Poor absorption; leaves residue |

| Polyester | Low | Poor absorption; weak bond |

Best Techniques for Applying Elmer’s Glue on Fabrics

- Preparation: Ensure the fabric is clean and dry. Any dirt or moisture can weaken the bond.

- Thin Layer Application: Apply a thin, even layer of glue to the fabric area you wish to bond. Too much glue can cause it to seep through the fabric and leave a residue.

- Pressing: Press the glued area with a weight or clamp to ensure a firm bond. This step is crucial for absorbent fabrics like cotton and felt.

- Drying Time: Allow sufficient drying time. Elmer’s Glue generally takes about 24 hours to fully dry. Avoid disturbing the glued area during this period.

- Testing: For large projects, conduct a small test on a fabric scrap to ensure the glue performs as expected.

Limitations

While Elmer’s Glue can be handy for lightweight crafts involving fabrics, it’s not suitable for projects that require a strong, flexible, or washable bond. For more demanding fabric projects, consider using fabric-specific adhesives or hot glue.

By understanding these nuances and applying Elmer’s Glue properly, you can achieve satisfactory results in your fabric projects.

Does Elmer’s Glue Hold Up on Wood?

The short answer is yes, Elmer’s Glue can effectively bond two pieces of wood together, but there are crucial factors to consider for optimal results.

Elmer’s Carpenter’s Wood Glue, specifically formulated for woodworking, is the best choice. It offers strong bonding strength and is designed to work with wood’s unique properties. For successful application, the wood surfaces must be properly prepared—sanded smooth and free of dust or grease.

Proper application involves spreading a thin, even layer of glue on both surfaces and then clamping them firmly until the glue dries. This ensures the bond is secure and durable. Elmer’s Carpenter’s Wood Glue is also water-based and non-toxic, drying clear and being easy to sand.

Here are some key points for effective wood bonding with Elmer’s Glue:

| Step | Details | Notes |

| Choose the Right Glue | Elmer’s Carpenter’s Wood Glue | Specifically formulated for wood |

| Surface Preparation | Sand and clean surfaces | Ensure surfaces are smooth and dust-free |

| Application | Apply a thin, even layer of glue | On both surfaces to be bonded |

| Clamping | Clamp the pieces together until dry | Ensures a strong bond |

| Drying and Sanding | Allow to dry, then sand if needed | Elmer’s Glue dries clear and can be sanded |

Using the wrong type of Elmer’s Glue, such as the basic white school glue, or neglecting proper surface preparation can lead to weaker bonds. For outdoor projects or those requiring extra durability, polyurethane glues like Gorilla Glue might be preferable.

Conclusion

Gluing concrete to concrete might sound unusual, but it’s a practical and robust solution for many construction and repair projects. Utilizing specialized adhesives like polyurethane mortar and epoxy, you can achieve strong, durable bonds between concrete surfaces.

Polyurethane mortar is flexible and ideal for environments with varying temperatures and humidity, making it perfect for outdoor projects like securing paving stones. Epoxy adhesives, known for their high strength and quick drying times, are excellent for heavy-duty applications such as structural repairs. Proper surface preparation is crucial; cleaning, drying, and roughening the concrete ensure optimal adhesion.

When applying the adhesive, tools like putty knives or caulking guns are effective. Pressing the surfaces together firmly and allowing proper curing time ensures a lasting bond. While Gorilla Glue can handle minor repairs, it may not be as effective for larger cured concrete surfaces.

Choosing the right adhesive and following meticulous preparation and application steps will guarantee the integrity and longevity of your concrete projects.