Have you ever faced the disappointment of a cherished ceramic piece meeting the unforgiving floor? The sinking feeling as you survey the scattered shards can feel like losing a little piece of history. But don’t sweep up the pieces in defeat just yet.

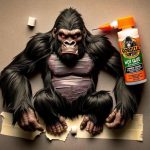

Enter the high-strength bond of Gorilla Glue – a potential savior for fractured ceramics. The question is: does it live up to its robust reputation?

So, can gorilla glue fix ceramic?

Gorilla Glue is a tough, expanding glue that can bond to virtually any surface, including ceramic. Gorilla Super Glue Clear is a good choice for quick fixes on ceramic because of its fast curing time, clear drying properties, and impact-resistant formula.

Whether you’re a DIY enthusiast or simply trying to save a piece of pottery with sentimental value, this discussion aims to equip you with the knowledge you need. Let’s find out if Gorilla Glue should be your go-to for ceramic crises, or if it’s best left on the store shelf.

Table of Contents

- 1 What is Gorilla Glue?

- 2 Benefits of Using Gorilla Glue on Ceramic

- 3 Preparing the Ceramic Surface for Glue Application

- 4 Applying Gorilla Glue to Ceramic

- 5 Clamping and Curing the Bonded Ceramic Pieces

- 6 Pros and Cons of Using Gorilla Glue on Ceramic

- 7 Special Considerations for Non-Porous Ceramics

- 8 Alternatives to Gorilla Glue for Ceramic Surfaces

- 9 Conclusion

What is Gorilla Glue?

Gorilla Glue is a robust, polyurethane-based adhesive renowned for its formidable bonding prowess.

It diverges from other adhesives in its chemical makeup and moisture-activated curing process, which enables it to join a diverse array of materials that other glues can’t handle as effectively.

Characteristics of Gorilla Glue:

- Versatility: Bonds wood, metal, glass, foam, ceramics, and more.

- Moisture-Activated: Requires moisture to cure, unlike other glues that dry by evaporation.

- Strength: Offers up to 3600 psi holding strength, outperforming many alternatives.

- Heat and Chemical Resistance: Ideal for demanding environments.

Comparison with Other Glues:

| Attribute | Gorilla Glue | Other Glues |

| Curing Mechanism | Moisture-activated | Typically evaporation-based |

| Bonding Strength | Up to 3600 psi | Varies, generally lower |

| Material Versatility | High (including difficult-to-bond materials) | Medium to low (limited by material type) |

| Resistance to Elements | High resistance to heat and chemicals | Varies, some may have lower resistance |

When mending ceramics, select the original, “brown” Gorilla Glue for its waterproof properties and natural drying colour. Preparing the surface, particularly with porcelain, is critical; a light sanding can enhance adhesion. Gorilla Glue is more suited for clean breaks rather than gaps, where specialized fillers might be necessary.

Keep in mind, Gorilla Glue’s formidable bonding might not be suitable for all scenarios, especially where flexibility is needed or for delicate repairs that require a less visible adhesive.

Benefits of Using Gorilla Glue on Ceramic

Gorilla Glue presents a plethora of benefits for mending ceramic treasures, thanks to its robust composition and distinctive features. Let’s delve into the specifics:

| Waterproof and Weatherproof | Gorilla Glue’s resilience to the elements makes it a champion for outdoor ceramic repairs, such as garden pottery and statuettes, safeguarding against moisture and temperature extremes. |

| Invisible Finish | It dries transparent, preserving the visual integrity of ceramics with elaborate patterns or sentimental value – a stealthy fixer-upper. |

| Formidable Bond | This adhesive boasts the muscle to support up to 30 pounds, perfect for hefty ceramic pieces, and it sets swiftly, slashing wait times. |

| Expanding Qualities | Upon setting, the glue expands to fill crevices, ensuring a snug, gap-free seal even on the most jagged of breaks. |

| Versatility | Adept at melding a spectrum of ceramics from porcelain to stoneware, and applicable to both glazed and unglazed surfaces, Gorilla Glue is a jack-of-all-ceramic repairs. |

Preparing the Ceramic Surface for Glue Application

To ensure a firm adhesion when applying Gorilla Glue to a ceramic surface, meticulous surface preparation is paramount. Here’s a step-by-step approach:

Cleaning the Surface

- Remove dirt and grime: Wash the ceramic with a gentle soap and water blend, scrubbing off any impurities.

- Dry thoroughly: Before proceeding, ensure the surface is completely dry to prevent dilution of the glue.

Inspecting and Smoothing

- Examine for damage: Check for any cracks or missing fragments that could affect the repair.

- Sand rough areas: Using sandpaper, smooth any uneven spots to prevent an irregular bond.

Preparing for the Glue

- Assemble materials: Have your Gorilla Glue and any fillers on hand, ready for use.

- Mixing fillers: If using a filler, prepare it according to the manufacturer’s instructions.

Glue Application

| Step | Action | Reason |

| Apply Glue | Place a modest amount of glue on one edge of the broken ceramic. | Prevents mess and ensures precision. |

| Align Pieces | Join the ceramic pieces carefully, pressing firmly for 10-20 seconds. | Secures the initial bond before curing. |

| Curing Time | Leave the object undisturbed for at least 24 hours. | Allows the glue to fully set and harden. |

| Excess Glue | Clean up any spillover with a moist cloth or sandpaper after drying. | Creates a clean finish without compromising the bond. |

Post-Application

- Avoid movement: Keep the ceramic still during the curing process to ensure a steadfast bond.

- Drying: Once you’ve wiped any spare glue, let the repair dry utterly before any further handling.

Applying Gorilla Glue to Ceramic

Preparation is Key

Before a single drop of Gorilla Glue touches your ceramic, you want to ensure you’ve set the stage for a bond that’s going to stick around, quite literally. Here’s the nitty-gritty on how to do just that:

Cleaning Matters

| Step: | Clean the Ceramic | Action: | Gently scrub with soapy water, rinse, and dry thoroughly. |

| Reason: | Ensures a debris-free surface | Outcome: | A stronger adhesive bond |

Surface Texture

| Step: | Sand the Surface | Action: | Use fine-grit sandpaper to roughen. |

| Reason: | Increases bonding area | Outcome: | Glue grips better |

Application

| Step: | Apply Gorilla Glue | Action: | Spread a thin layer on one surface. |

| Reason: | Prevents over-expansion | Outcome: | No messy squeeze-out |

Pressure and Alignment

| Step: | Clamp Surfaces | Action: | Align and apply pressure with clamps. |

| Reason: | Encourages strong bond formation | Outcome: | Surfaces stay put as glue cures |

Curing

| Step: | Allow to Cure | Action: | Leave undisturbed for 24 hours, ideally 72 hours for full strength. |

| Reason: | Maximizes bond integrity | Outcome: | Long-lasting hold |

Tips and Tricks

- If you’re dealing with a vertical ceramic surface, opt for Gorilla Glue with a gel-like consistency to avoid drippy disasters.

- Zig-zag patterns can be your best mate for larger surface areas, ensuring the glue is evenly spread.

- Got a bit of glue seeping out the sides? A damp cloth will clean up your act before the glue sets.

By sticking to these steps, you’ll give your ceramic the best shot at a lasting bond. Remember, patience is not just a virtue but a necessity when it comes to adhesion.

Clamping and Curing the Bonded Ceramic Pieces

When using Gorilla Glue for bonding ceramic pieces, clamping is a critical step to ensure a strong and durable bond.

| Initial Clamping Time | 20-30 minutes | Essential to hold pieces in place |

| Handling Time | 1-2 hours | Wait before moving or touching |

| Full Cure Time | 24 hours | For maximum bond strength |

Curing Process:

Once clamped, do refrain from disturbing the pieces. A stout bond forms as the adhesive reacts and cures. After the initial clamping period, give the piece a standing time of one to two hours before any gentle handling.

It’s wise to leave the bonded ceramic undisturbed, resting in a safe spot, permitting the glue to cure thoroughly, which typically takes an entire night’s span. Come morn, you’ll find the bond tough as nails, ready for whatever task lies ahead.

Pros and Cons of Using Gorilla Glue on Ceramic

Benefits of Using Gorilla Glue on Ceramic

| Strength and Durability | Gorilla Glue is known for its formidable bonding power and resilience against extreme conditions. |

| Versatility | Its capability to adhere to various surfaces makes it a versatile option for multiple types of ceramic projects. |

| Gap Filling | The glue’s expanding nature allows it to fill gaps effectively, ensuring a robust bond even on uneven breaks. |

Drawbacks of Using Gorilla Glue on Ceramic

| Messiness | The thick consistency of the glue can be tricky to handle, leading to a sticky situation if not managed properly. |

| Moisture Activation | It requires moisture to trigger its adhesive properties, which might not be ideal in all circumstances. |

| Expansion During Curing | As it cures, the glue expands, potentially causing seepage or distortion of the ceramic pieces if applied excessively. |

| Long Drying Time | With a curing time of over 24 hours, it demands patience and proper clamping to avoid weak bonds. |

Gorilla Glue’s tenacity and gap-filling capabilities make it a solid choice for mending ceramics, but handling its syrupy consistency and allowing ample time for it to cure are key to a successful fix.

Special Considerations for Non-Porous Ceramics

When repairing non-porous ceramics, it’s essential to choose the right adhesive to secure a steadfast mend. Gorilla Glue is a robust option, with various formulations tailored to different materials. Here’s the scoop on using Gorilla Glue with non-porous ceramics:

| Type of Gorilla Glue | Best Use | Why It Works |

| Original Gorilla Glue | Non-porous surfaces requiring a waterproof bond | It’s polyurethane-based and expands into materials for a strong bond. Needs moisture to activate. |

| Epoxy Gorilla Glue | Non-porous ceramics needing a gap-filling adhesive | Its thicker consistency is ideal for smooth surfaces and doesn’t require moisture to cure. |

For non-porous ceramics like porcelain, your best bets are the Original or Epoxy Gorilla Glue. The Original formula is grand for surfaces that can handle a little moisture, while Epoxy is top-notch for those smooth, moisture-scarce surfaces. Both promise a sturdy bond, but remember, cleanliness is next to godliness here. Before you start, ensure the ceramic is spotless – a quick swipe with rubbing alcohol does the trick.

To sum up, yes, Gorilla Glue can stick to non-porous ceramics. Just pick the right type and prep your surfaces like a pro.

Alternatives to Gorilla Glue for Ceramic Surfaces

When mending ceramics, it’s not just about sticking pieces together—it’s about choosing an adhesive that blends strength with subtlety. Below is a table that outlines some top-notch alternatives to Gorilla Glue, each with its unique benefits for ceramic repair.

| Adhesive Type | Best For | Key Features |

| Epoxy Glue | Large or heavy ceramics | Two-part adhesive, strong after mixing, durable |

| Super Glue (Cyanoacrylate) | Quick fixes, small repairs | Bonds quickly, suitable for hairline cracks |

| Clear Silicone Adhesive | Delicate items, food-related ceramics | Waterproof, heat-resistant, dries clear |

| Specialised Ceramic Glue | Specific ceramic applications | Designed for ceramics, may offer temperature resistance or flexibility |

Epoxy glue is a real champ for those hefty ceramic items, think big vases or those hefty art pieces. It’s sturdy as an ox after curing, and it’ll take a lot to knock it down.

Then there’s super glue, the sprinter of adhesives. It sets off fast, perfect for a quick touch-up on those little chips and cracks. But remember, it’s not the best mate for the heavy stuff.

If you’ve got something a bit more dainty, like your grandma’s fine china or a posh porcelain figurine, you’d want to go with clear silicone adhesive. It’s the invisible cloak of glues, drying clear so it won’t cramp your style, all the while being tough against water and heat.

And for those special ceramic fixes, there are glues out there made just for these occasions. They might cost a bit more, but they’re tailored for the job, offering qualities like flexing with the heat or sticking tight in tricky situations.

Conclusion

In the struggle to repair shattered ceramics, Gorilla Glue proves to be a strong ally. We’ve looked at the science behind Gorilla Glue’s remarkable adhesive properties throughout the essay, including its moisture-activated curing process and amazing strength of up to 3600 psi. We’ve also included a comprehensive tutorial on using Gorilla Glue correctly, which will guarantee a long-lasting and attractive repair.

This polyurethane-based adhesive has obvious advantages when applied to ceramics: it is windproof, watertight, and, once dry, provides an undetectable finish. Its expanding properties make it perfect for filling in spaces between sharp fractures, and its adaptability allows it to work with a variety of ceramic kinds. To provide the best adhesion, it is important to properly clean and sand the ceramic surface.

The post isn’t afraid to provide substitutes or point out circumstances in which Gorilla Glue may not be the ideal option, such need for flexibility or repairs that call for a less obvious glue. Nevertheless, Gorilla Glue sticks out as a strong and dependable choice for several ceramic repair situations.