Do you know that each year in the United States alone, over one million injuries occur due to staircase accidents? While the causes of these mishaps vary, the stability and security of stair treads play a pivotal role in ensuring safe navigation of stairs. This brings us to a crucial question: Can you use Liquid Nails for stair treads? Despite its popularity in other construction realms, Liquid Nails might not be your best bet for this particular task.

So, can i use liquid nails for stair treads?

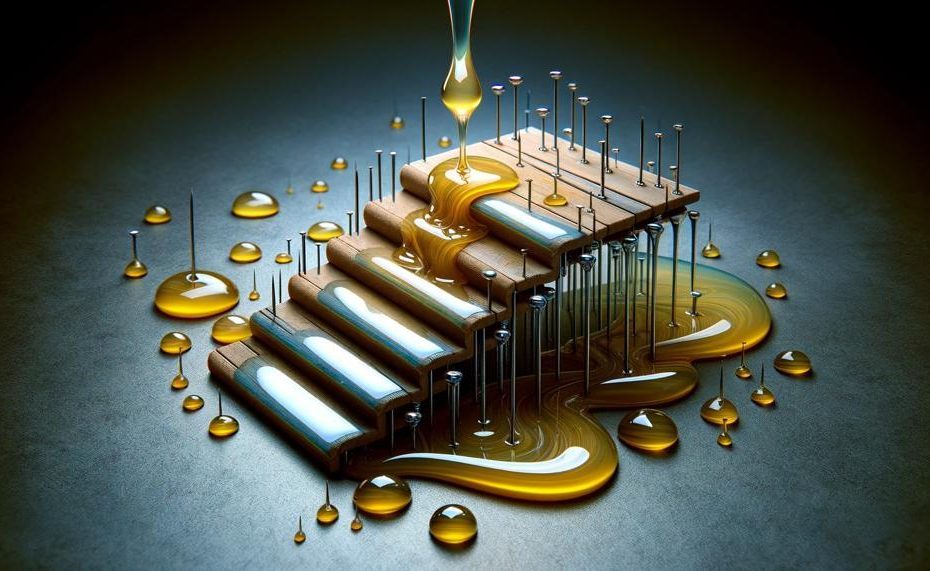

Yes, you can use Liquid Nails for stair treads1. Liquid Nails is a brand of adhesive renowned for its strength and versatility. It’s particularly suitable for securing stair treads due to its exceptional bonding properties, durability, and resistance to moisture.

However, it’s important to follow proper application techniques for the best results1. Here are some steps you can follow:

- Prepare the Surface: Ensure that the tread surface is clean, dry, and free from any debris or contaminants.

- Apply Liquid Nails: Apply the adhesive in a zigzag pattern on the back of each tread for optimal coverage and adhesion.

- Press and Secure: Press each stair tread firmly onto the surface to ensure full contact. Consider using clamps or weights if necessary to hold the treads in place while the adhesive cures.

In this blog post, we will explore these aspects in detail, weighing the pros and cons of using Liquid Nails versus more traditional methods. Our goal? To ensure that you make an informed decision that prioritizes safety and durability.

Let’s step into a thorough discussion on what truly holds up when it comes to securing stair treads.

Table of Contents

- 1 What is Liquid Nails?

- 2 What are Stair Treads?

- 3 Compatibility of Liquid Nails and Stair Treads Material

- 4 Weight-Bearing Capacity of Adhesive

- 5 Proper Surface Preparation

- 6 Application Technique for Maximum Strength and Durability

- 7 Curing Time for Liquid Nails

- 8 Long-Term Maintenance and Repairability of Stair Treads Installed with Liquid Nails

- 9 Conclusion

What is Liquid Nails?

Liquid Nails is a brand of strong adhesive primarily designed for heavy-duty construction purposes. Unlike ordinary glues, Liquid Nails is engineered to create durable, long-lasting bonds across a diverse range of materials including wood, metal, and plastics.

It’s especially favored for projects that require superior strength and resistance to weather conditions, making it ideal for both indoor and outdoor applications.

Comparison between Liquid Nails and Other Types of Glue

| Type of Adhesive | Primary Use | Material Compatibility | Strength and Durability | Setting Time |

| Liquid Nails | Construction and heavy-duty applications | Wood, metal, plastics, and more | High strength, weather-resistant | Varies, generally longer to cure |

| Wood Glue | Woodworking projects | Primarily wood | Strong on wood, not weather-resistant | Faster, ideal for quick repairs |

| Super Glue | Quick fixes, small-scale bonding | Mostly non-porous materials | Very high strength, not flexible | Seconds to minutes |

Distinguishing Features of Liquid Nails:

- Versatility: Liquid Nails can be used on a broad range of materials, unlike wood glue which is best for wood or super glue designed for small, quick repairs.

- Durability: The formula is designed to withstand harsh environmental conditions, offering a bond that is both strong and flexible compared to the brittle finish typical of super glues.

- Application: Ideal for projects requiring a robust adhesive solution, such as construction, remodelling, and outdoor fixtures, where different materials need to be bonded together reliably.

Choosing the Right Adhesive:

When deciding between Liquid Nails and other adhesives, consider the materials involved, the environmental exposure, and the durability required.

Liquid Nails stands out for tasks demanding superior holding power and resilience, whereas other glues might be preferable for more delicate or precision-focused applications.

What are Stair Treads?

Stair treads are the horizontal parts of the stairs where one steps when ascending or descending. They play a crucial role in stairway design and safety.

The importance of stair treads lies in their function and regulatory requirements, making them integral to any staircase installation.

Key Functions and Importance:

- Safety: Treads provide a secure platform, reducing the risk of slips and falls. Their dimensions and surface textures are designed to offer adequate foot grip.

- Comfort: The depth of a tread impacts the comfort level when using the stairs. A well-sized tread allows for a natural gait, making the staircase more ergonomic.

- Aesthetic and Design Flexibility: Treads offer various material choices—wood, metal, stone, or carpeted options—each contributing to the staircase’s overall look and feel.

- Compliance with Building Codes: Proper tread size and spacing are governed by local building codes, which ensure safe and accessible stair design.

Detailed Specifications in Table:

| Feature | Function | Regulatory Importance |

| Safety Surface | Prevents slipping | Mandatory in building codes |

| Depth of Tread | Facilitates comfortable foot placement | Specific dimensions dictated by codes |

| Material Variety | Enhances aesthetic appeal | Flexible to suit design preferences |

The installation of stair treads must be meticulously planned and executed to ensure they meet both the aesthetic goals of a building project and the stringent safety standards required by law.

Compatibility of Liquid Nails and Stair Treads Material

Yes, certain stair tread materials may not be compatible with Liquid Nails adhesive, which could affect the durability and safety of the staircase. It’s pivotal to choose the right adhesive for the material you are working with to ensure optimal performance and longevity.

Here’s a breakdown of common stair tread materials and their compatibility with Liquid Nails:

| Material | Compatibility | Notes |

| Wood | Compatible | Liquid Nails can be effective for wooden stair treads, ensuring a firm bond if properly applied. |

| Laminate | Not Recommended | Adhesives like Liquid Nails may not bond effectively with laminate surfaces, which can lead to peeling and shifting. |

| Carpet | Not Recommended | Using Liquid Nails on carpeted treads can cause damage to the carpet fibers and inadequate adhesion. |

| Vinyl | Moderately Compatible | Special care must be taken to ensure the surface is clean and dry for the adhesive to work effectively on vinyl. |

| Rubber | Not Recommended | Rubber’s elasticity and texture often prevent strong adhesion with general-purpose adhesives like Liquid Nails. |

For optimal results, stair tread installation should be approached with precision. The material’s nature and the adhesive’s properties need to be in sync. While Liquid Nails might serve well for more porous materials like wood, its efficacy dwindles with non-porous, flexible, or smooth surfaces such as laminate, carpet, and rubber.

Weight-Bearing Capacity of Adhesive

To ascertain the weight-bearing capacity of Liquid Nails for stair treads, it is essential to delve into the specifics of both the adhesive and the tread material. Each stair tread material—from wood to laminate—dictates a unique bonding strategy and influences the strength of the adhesive bond. The steps below outline the best practices for ensuring the durability and safety of your stair installation using Liquid Nails.

- Select the Correct Liquid Nails Formula: With various formulations available, selecting an adhesive that corresponds with your tread material is crucial. For instance, a formula that is effective for wood may not suit vinyl or rubber surfaces.

- Surface Preparation: Ensure that the tread surface is thoroughly cleaned and dried. Any debris or moisture can significantly weaken the bond.

- Application Technique: Apply the adhesive in a zigzag pattern across the back of the tread to maximize contact area. This method helps distribute the load evenly.

- Adherence to Manufacturer’s Guidelines: Refer to the Liquid Nails packaging for specific instructions regarding drying times and load capacities. These guidelines are tailored to the chemical properties of the adhesive.

- Evaluation of Long-term Durability: Consider the environmental factors like humidity and temperature, which can affect the adhesive’s longevity and strength.

Using the table below, you can find a guideline on the approximate weight capacities for different Liquid Nails formulations when used with common stair tread materials.

| Adhesive Type | Material Compatibility | Approx. Weight Capacity |

| Liquid Nails Construction Adhesive | Wood, Laminate | Up to 80 lbs per square inch |

| Liquid Nails Heavy Duty | Wood, Vinyl, Rubber | Up to 100 lbs per square inch |

| Liquid Nails Subfloor Adhesive | Wood, Carpet | Up to 120 lbs per square inch |

By following these steps and considerations, you can effectively determine and utilize the weight-bearing capacity of Liquid Nails to secure stair treads.

Proper Surface Preparation

To guarantee a robust bond when installing stair treads with Liquid Nails, it’s paramount to meticulously prepare the surface. Below, the essential steps are outlined to ensure that the surface is optimal for adhesive application.

- Clean the Surface: Begin by cleaning the surface to remove all traces of dirt, dust, and debris. A broom or vacuum can be effective for this initial sweep.

- Remove Existing Coatings: If the surface has any previous coatings, these must be removed. For surfaces with paint or varnish, sanding is necessary to create a rough texture for better adhesive grip.

- Roughen the Surface: Use medium-grit sandpaper to further roughen the surface, enhancing the adhesive’s ability to bond.

- Inspect and Repair: Before proceeding, inspect the surface for any loose boards or cracks. Repair these imperfections to ensure a smooth and even application area.

- Choose the Right Adhesive: Select a Liquid Nails product that is compatible with the material of your stair treads. This ensures optimal performance and durability.

- Application of Adhesive: Apply the adhesive in a generous zigzag pattern on the back of each tread, ensuring thorough coverage.

- Press and Set: Firmly press each tread onto the prepared surface, ensuring full contact with the adhesive. Use a roller or similar tool to apply even pressure across the tread.

- Allow to Dry: Finally, allow the adhesive to set for the time recommended by the manufacturer before using the stairs to avoid shifting or displacement of the treads.

Application Technique for Maximum Strength and Durability

To ensure maximum strength and durability when applying liquid nails to stair treads, follow these meticulously detailed steps, arranged in a straightforward yet comprehensive format.

| Step | Action | Details |

| Surface Preparation | Clean and Dry | Ensure the stair tread surface is devoid of debris, dust, and moisture. This foundational step is crucial for optimal adhesive bonding. |

| Adhesive Selection | Choose Correctly | Use an adhesive compatible with your tread material. Reference the manufacturer’s guidelines to select the right liquid nails product. |

| Application Pattern | Zigzag Bead | Apply a generous, thick bead of liquid nails in a zigzag pattern across the back of each tread, ensuring comprehensive coverage. |

| Secure Placement | Press Evenly | Position the tread onto the step, pressing down firmly and evenly across its surface to establish a strong, uniform bond. |

| Curing Time | Allow to Set | Follow the drying time recommended by the liquid nails manufacturer before stepping on or loading the stairs to prevent shifting. |

| Additional Support | Clamps/Weights | For extra security while the adhesive sets, use clamps or weights to maintain pressure on the treads, enhancing the bond strength. |

| Safety First | Patience in Curing | Give the adhesive ample time to cure completely before using the stairs to avoid potential mishaps or premature wear. |

| Quality Materials | Choose Wisely | Opt for high-quality stair treads designed for adhesive compatibility to improve overall durability and adhesion quality. |

| Maintenance | Regular Checks | Regularly inspect and maintain the treads to ensure long-term durability and safety. |

Each step is critical not only for the immediate installation but also for the long-term usability and safety of the stairs.

Curing Time for Liquid Nails

The curing time for Liquid Nails when applied to stair treads generally takes around 24 hours for a skin to form and up to 7 days for a complete cure, making it a rather slow setter in the world of adhesives. The exact time can vary based on environmental factors like humidity and temperature, as well as the materials involved.

For stair treads, where a durable, steadfast bond is essential, adhering strictly to optimal application practices enhances the strength and effectiveness of the bond.

| Initial Setting Time | Approximately 15 minutes for initial grab | Can vary slightly depending on temperature and humidity |

| Time to Form Skin | 24 hours | Essential before subjecting to any movement |

| Full Cure Time | Up to 7 days | Depends on conditions and materials used |

For securing stair treads, it’s vital to consider that while Liquid Nails provides an initial strong grab, full functionality and load-bearing capacity isn’t reached until after the complete curing period.

During this time, maintaining a stable environment without exposure to heavy loads or extreme temperatures will facilitate optimal adhesive performance.

Long-Term Maintenance and Repairability of Stair Treads Installed with Liquid Nails

The key to maintaining stair treads affixed with liquid nails lies in ongoing vigilance and appropriate upkeep. Here’s how you can ensure they remain secure and aesthetically pleasing over time:

Regular Inspection and Cleaning

- Check Regularly: Inspect the treads monthly for signs of wear or loosening. Listen for creaks or movement, which could indicate the adhesive is weakening.

- Clean Treads: Remove dirt and debris to prevent accumulation that can stress the adhesive bond. Use a soft brush and a mild cleaning solution.

Immediate Attention to Damages

- Address Wear: If a tread becomes damaged, address it promptly. Prolonging repairs can lead to further deterioration, which compromises both safety and aesthetics.

- Consult a Professional: For significant repairs, it might be beneficial to consult a professional to ensure the integrity of the treads and underlying surfaces.

Mindful Use of Materials

- Choose Quality Over Cost: Invest in high-quality stair treads and adhesive. This investment upfront can reduce the frequency and complexity of maintenance down the line.

- Compatibility Check: Ensure the materials of the stair treads are compatible with liquid nails for optimal bonding.

Avoid Harsh Chemicals

- Gentle Cleaning Agents Only: Avoid using harsh chemicals that could degrade the adhesive. Stick to mild, non-abrasive cleaners to protect both the stair treads and the bonding agent.

Periodic Professional Reviews

- Annual Check-ups: Consider having the stair treads inspected annually by a professional. This can help catch issues that are not obvious to the untrained eye, ensuring the longevity of your stairs.

Maintenance

To simplify, here’s a practical guide to follow for maintaining your stair treads:

| Task | Frequency | Details |

| Inspection | Monthly | Check for signs of wear or loosening. Listen for any sounds of movement. |

| Cleaning | As needed | Use a soft brush and mild cleaner to remove dirt and prevent buildup. |

| Professional Review | Annually | Have the stair treads and adhesive inspected by a professional. |

Conclusion

In the realm of home improvement, ensuring the safety and durability of staircases is paramount. Liquid Nails, while a robust adhesive known for its strong initial grip across various construction projects, may not be the best candidate for securing stair treads. This is primarily due to the intricacies involved in its application and the potential complications it presents for future modifications or repairs.

The efficacy of Liquid Nails depends heavily on selecting the appropriate formula tailored to the material of your stair treads, be it wood, laminate, or carpet. Although it can provide a sturdy initial bond, alternatives such as mechanical fasteners—screws or nails—are recommended for their reliability and ease of adjustment over time.

For homeowners considering the use of Liquid Nails for stair treads, it is crucial to weigh the pros and cons. Opting for mechanical fasteners might involve more upfront effort but pays dividends in long-term stability and safety.