Are you tired of your adhesive failing to hold things together? This beloved bonding agent has been a household essential for decades. It is renowned for its rapid and robust sticking abilities.

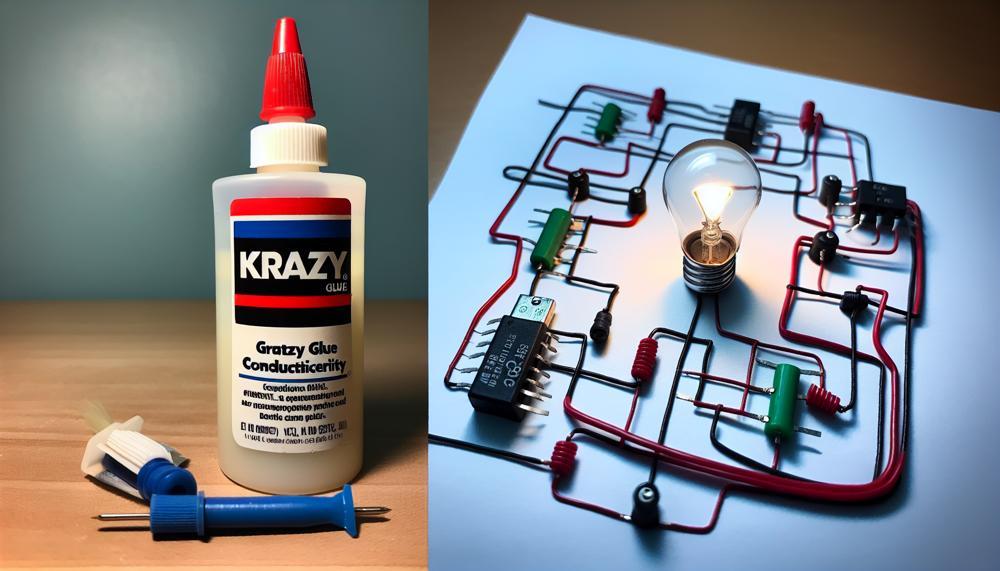

But did you know that Krazy Glue isn’t just great at adhering objects, but also at conducting electricity?

That’s right. This versatile glue has remarkable electrical properties that set it apart from other adhesives on the market.

In this blog post, we’ll delve into the fascinating world of Krazy Glue conductivity. We’ll also explore its surprising applications. Get ready to discover:

- The science behind conductivity and how it relates to Krazy Glue

- Real-life examples of using Krazy Glue as an electrical conductor

- Tips and tricks for optimizing the conductivity of Krazy Glue in your projects

- Common misconceptions about using Krazy Glue for electrical purposes

- And much more.

So, grab your preferred adhesive and prepare to be amazed by the impressive conductivity of Krazy Glue.

Let’s jump in.

Table of Contents

- 1 What glue is electrically conductive

- 2 Is krazy glue conductive?

- 3 Types of Conductive Glue

- 4 Adhesive Matrix and Electrical Conductivity

- 5 Application Methods for ECA

- 6 Factors Affecting Electrical Conductivity

- 7 Industries Where ECA is Used

- 8 Considerations When Choosing an ECA

- 9 Advantages of Using Electrically Conductive Glue

- 10 Disadvantages of Using Electrically Conductive Glue

- 11 Conclusion

What glue is electrically conductive

Electrically conductive glue, also known as conductive adhesive, not only bonds materials but also allows electricity to pass through it. This unique property makes it a popular choice in various industries. These include electronics, automotive, aerospace, and medical devices.

There are several types of conductive glue available, each with its own set of benefits and applications.

- Carbon-based conductive glue contains carbon particles and binders and is commonly used in intricate electronic circuits or fixing damaged traces on PCBs.

- Silver-based conductive glue, on the other hand, uses silver particles and epoxy resin and is suitable for high-frequency bonding and chip packaging.

- Nickel and copper-based conductive glue use nickel or copper particles and binders and are ideal for bonding substrates with different thermal expansion coefficients. Lastly, graphene-based conductive glue utilizes graphene sheets and binders and is perfect for wearable electronics and flexible circuits.

- Conductive glue is widely used in various applications due to its ability to bond materials while also providing electrical conductivity. For example, it is often used in electronic circuits to fix damaged traces on PCBs or create connections between components.

- In chip packaging, silver-based conductive glue is commonly used to ensure efficient electrical transfer.

- Graphene-based conductive glue is ideal for bonding flexible circuits in wearable electronics due to its excellent electrical conductivity and flexibility.

Is krazy glue conductive?

No, Krazy Glue is not conductive. It is an adhesive used to bond materials together. It does not conduct electricity.

Table: Krazy Glue Properties

| Property | Value |

| Conductivity | Non-conductive |

| Adhesive Type | Cyanoacrylate |

| Color | Clear |

| Viscosity | Thin |

| Setting Time | Fast |

| Tensile Strength | 2500 psi |

Additional Information

- Krazy Glue is a brand name for cyanoacrylate glue, a type of fast-acting adhesive that bonds to a variety of materials, including metal, plastic, rubber, and wood.

- Cyanoacrylate glues work by forming a strong chemical bond between the two surfaces being joined. This bond is not conductive. Krazy Glue cannot be used to repair electrical circuits or other applications where conductivity is required.

- There are other types of glue that are conductive, such as silver epoxy and conductive carbon paint. These glues are specially formulated to conduct electricity. They are used in applications such as repairing printed circuit boards and creating electrical connections.

- When choosing a glue for a particular application, it is important to consider the conductivity of the glue. If conductivity is required, a conductive glue should be used. If conductivity is not required, a non-conductive glue like Krazy Glue can be used.

Types of Conductive Glue

There are four main types of conductive glue. They are: carbon-based, silver epoxy, nickel and copper conductive adhesives, and graphene-based. Each type has its own special characteristics and uses, making them suitable for a variety of industries and purposes.

- Carbon-based conductive glue is made up of a carbon-based material, typically graphite or carbon black, mixed with an adhesive binder. It is commonly used in the electronics industry. People use it for repairing damaged traces and creating intricate circuits. This type offers strong adhesion and good electrical conductivity at a reasonable cost. However, it may not have as high conductivity as other types of conductive glue.

- Silver epoxy conductive glue is composed of silver particles suspended in an epoxy resin binder. It is often used in the semiconductor industry for chip packaging and high-frequency bonding. This type offers excellent electrical conductivity and strong bonding strength. It is a popular choice for critical electronic applications. However, it can be more expensive and requires special handling due to its sensitivity to temperature and humidity.

- Nickel and copper conductive adhesives are produced by combining nickel or copper particles with an adhesive binder. They are often used in the electronics industry as an alternative to traditional soldering techniques. These types provide good electrical conductivity and versatility. They bond different materials and are suitable for many applications. However, they may not have as strong bonding strength as other types of conductive glue.

- Graphene-based conductive glue is made up of graphene, a form of carbon, mixed with an adhesive binder. It offers exceptional electrical conductivity, thermal properties, and flexibility. This makes it perfect for wearable electronics and flexible circuits. Additionally, it boasts robust bonding strength. It can bond to various surfaces without additional preparation. However, it may be more expensive than other types of conductive glue.

Adhesive Matrix and Electrical Conductivity

The adhesive matrix of Krazy Glue plays a critical role in determining its electrical conductivity. Krazy Glue, also known as cyanoacrylate adhesive, is a non-metallic adhesive. It is not intended or recommended for use in electrical applications.

Its molecular structure creates an imbalance that hinders the free flow of electrons, making it a poor conductor of electricity.

The adhesive matrix of Krazy Glue is composed of monomers. Monomers are small molecules that bond together to form long chains called polymers. These polymers give Krazy Glue its strong bonding properties. They also contribute to its lack of electrical conductivity.

The molecules in the adhesive matrix are not arranged in a way that allows for easy electron flow. This results in high resistivity.

When using Krazy Glue for electrical applications, the thickness and quality of the glue bond are key factors to consider.

While it may still conduct electricity when used to bond two conductive materials together, it is not a reliable choice compared to other conductive adhesives specifically designed for electrical purposes.

Application Methods for ECA

There are several ways to apply ECA. These include dispensing, screen printing, stenciling, and spray coating.

If you are using krazy glue as your ECA, the most effective method is dispensing it through a manual dispenser. This is because it has low viscosity.

Factors Affecting Electrical Conductivity

Various factors, like chemical composition and physical properties, determine the electrical conductivity of a substance. Krazy glue’s ability to allow electricity to flow through it also plays a role.

These factors work together to determine the level of conductivity for each substance. Impurities or additives present can affect the conductivity. Understanding these factors is crucial in determining how a substance can be used and its potential for electrical conduction.

| Factors That Affect Electrical Conductivity | Description | Examples |

| Chemical Composition | The elements and compounds that make up a substance. | The primary ingredient of krazy glue is cyanoacrylate. |

| Physical Properties | The molecular structure, density, and state of a substance. | Solids generally have higher conductivity than liquids or gases. |

| Ability to Allow Electricity to Flow | The presence of free electrons within the substance. | In conductive substances, like metals, there are numerous free electrons available for electricity to flow through. |

| Impurities and Additives | Substances that can affect the conductivity levels of a material. | Pure gold has high conductivity, but adding impurities can decrease it. |

Industries Where ECA is Used

ECA, or Export Credit Agencies, is widely used in a range of industries. This includes construction, energy, transportation, manufacturing, and more. Its primary purpose is to promote exports and facilitate international trade. It also offers an array of benefits to these industries.

- Construction industry: ECA plays a vital role in financing large-scale infrastructure projects like bridges, roads, and airports. It provides funding options for both contractors and buyers, making it easier for them to complete these projects successfully.

- Energy industry: ECAs offer financing for renewable energy projects such as wind farms and solar power plants. They also provide risk mitigation strategies for energy companies investing in foreign markets.

- Transportation industry: ECAs support the export of transportation equipment such as airplanes, trains, and ships. Additionally, they offer financing options for manufacturers and buyers of these products.

- Manufacturing industry: ECAs facilitate the export of goods produced by manufacturing companies by providing financing options and risk insurance. This promotes international trade and helps these companies expand their sales volume globally.

- Agricultural industry: ECAs support the export of agricultural products by providing financing options and risk insurance for these transactions. This helps farmers and agricultural companies reach new markets and increase their revenue.

Apart from these industries, ECAs also benefit other sectors such as healthcare, telecommunications, and consumer goods. They promote exports and help companies manage risks in international trade.

Considerations When Choosing an ECA

When considering which ECA to use for a particular project or application, you must take several factors into account. These include the type of surface or material being worked on, the desired level of conductivity, the surrounding environmental conditions, the time needed for curing, and the specific process being used. Each of these factors plays a crucial role in determining the most suitable ECA for the job at hand.

For example, if you are working with a delicate substrate that could be easily damaged by harsh chemicals, you would need to choose an ECA that is safe to use on such surfaces. On the other hand, if your project requires high conductivity levels, you would need to select an ECA specially formulated for this purpose. Additionally, consider environmental factors like extreme temperatures and humidity levels. This is essential to ensure the effectiveness and longevity of the chosen ECA.

Another critical aspect to consider is the curing time required for the ECA. Some projects may have strict deadlines, requiring a fast-curing ECA to be used. In contrast, other applications may allow for longer curing times. Finally, understanding the specific process being used is crucial. It helps in determining which ECA will provide optimal results.

By carefully evaluating these considerations when selecting an ECA, you can ensure that your project will be successful and efficient in meeting its objectives.

Advantages of Using Electrically Conductive Glue

Many industries prefer electrically conductive glue because it has several advantages over traditional glues. Its exceptional properties make it a versatile adhesive option for various applications. Here are the main benefits of using electrically conductive glue:

- Electrical conductivity: The most significant advantage of electrically conductive glue is its ability to maintain electrical conductivity while bonding electronic components. This is crucial in industries such as electronics, where proper functioning of circuits and connections is essential.

- Versatility: With its unique combination of stickiness and electrical conductivity, electrically conductive glue can be used for various purposes, including intricate electronic circuits, repairing damaged traces, and attaching components to PCBs.

- Eliminates soldering: Conductive glue eliminates the need for traditional soldering techniques, which can be time-consuming and require specialized equipment. This makes it a more efficient and cost-effective option.

- Excellent properties: Conductive glues exhibit excellent properties such as high thermal stability, flexibility, and compatibility with different substrates. This allows for a wide range of applications in various industries.

- Ease of use: Unlike soldering, which requires specialized skills and equipment, electrically conductive glue is easy to use and apply. This makes it a popular choice for DIY projects or small-scale production.

- Wide range of options: There are various types of conductive glues available in the market, such as carbon-based, silver epoxy, nickel and copper, and graphene-based. This allows for flexibility in selecting the most suitable option for specific project requirements.

- Cost-effective: Although electrically conductive glue may have a higher initial cost compared to traditional glues, it eliminates the need for additional equipment and specialized skills, making it a more cost-effective option in the long run.

- Non-toxic: Many traditional glues contain harmful chemicals that can be hazardous to health and the environment. On the other hand, electrically conductive glue is often non-toxic and safer to use.

Overall, the use of electrically conductive glue offers a multitude of advantages over traditional glues, making it a popular choice for various industries and applications.

However, when selecting an electrically conductive glue for a project, it is essential to carefully consider factors such as substrate materials, cure time, and process compatibility.

For example, I once had to repair a damaged electronic circuit board for my brother’s car. I used electrically conductive glue, and it worked like a charm. The repair was quick and easy, thanks to the versatility and ease of use of the glue.

Disadvantages of Using Electrically Conductive Glue

Using electrically conductive glue has numerous potential disadvantages. This is especially true when comparing it to other types of adhesives. These include:

- Limited Fundamentals: Electrically conductive adhesives are a relatively new technology, and there is still a lack of fundamental knowledge regarding their properties and performance. This can make it challenging to predict their long-term behavior.

- Insufficient Long-Term Data: As electrically conductive adhesives are a newer technology, there is also a lack of long-term performance data available. This can make it difficult to assess their reliability and durability over time.

- Electrical Performance Over Time: While electrically conductive adhesives offer excellent initial electrical conductivity, there may be concerns about how this conductivity will hold up over the lifespan of the bond. Joint resistance can increase over time, leading to potential issues with electrical performance.

- Meeting Specifications: Industries with strict specifications for their products may struggle to find electrically conductive adhesives that meet their requirements. Finding adhesives that meet both electrical and mechanical specifications can be challenging.

- Production and Training Time: Implementing electrically conductive adhesives into manufacturing processes may require significant time and resources for productionization and training operators on the new process.

- Lower Thermal and Electrical Resistance: Compared to traditional soldering methods, electrically conductive adhesives have higher electrical and thermal resistances. This can lead to decreased performance in certain applications.

- Longer Curing Time: While electrically conductive adhesives require lower temperatures for curing, they often take longer than traditional soldering methods. This can slow down production processes.

- Cost: Silver is commonly used in electrically conductive adhesives, which can make them more expensive compared to other types of adhesives. This may not be feasible for use on a larger scale or in cost-sensitive industries.

Conclusion

In conclusion, Krazy Glue is not just your ordinary adhesive. It’s a game-changer in the world of electronics.

We delved into its fascinating conductivity. We discovered how its exceptional electrical properties have revolutionized various industries. Along the way, we debunked misconceptions and shared tips for maximizing its conductivity.

Krazy Glue is a versatile and reliable solution for intricate circuitry and fixing damaged PCBs.